RFID Solutions

RFID Solution Overview

RFID is an automatic tracking technology using radio waves. It surpasses barcodes by allowing simultaneous, non-line-of-sight scanning for real-time inventory management and security.

Manual processes often create significant business challenges, including inaccurate inventory, supply chain opacity, data entry errors, and security risks like theft. RFID (Radio-Frequency Identification) technology directly solves these issues by using radio waves to automate tracking. By enabling simultaneous scanning of multiple items without a direct line of sight, RFID eliminates manual bottlenecks, provides real-time visibility of assets, and ensures end-to-end traceability for compliance. This enhances productivity, improves security with unique IDs, and prevents losses, making it a cornerstone of the modern, efficient supply chain.

Why Adopt RFID Solution

Adopting an RFID solution offers a transformative approach to business operations, delivering tangible benefits that address critical pain points and drive competitive advantage:

- Improved Inventory Accuracy: RFID enables near-perfect inventory accuracy (up to 98-99%) by automating data capture, significantly reducing manual errors and eliminating the need for time-consuming physical counts. This leads to better stock management, reduced carrying costs, and fewer stockouts.

- Enhanced Operational Efficiency: By automating processes like receiving, picking, packing, and shipping, RFID drastically reduces manual labor and streamlines workflows. This accelerates operations, minimizes delays, and boosts overall productivity.

- Real-time Visibility and Control: RFID provides continuous, real-time tracking of items, assets, and processes throughout the supply chain. This unparalleled visibility empowers businesses to make informed decisions, optimize resource allocation, and respond proactively to changes.

- Significant Cost Reduction: Automation through RFID reduces reliance on manual labor, minimizes errors, and optimizes inventory levels, leading to substantial cost savings in labor, reduced shrinkage, and improved asset utilization. The technology can offer a rapid return on investment (ROI).

- Superior Asset Tracking: RFID offers accurate and punctual tracking of individual assets, from tools and equipment to high-value machinery. This prevents loss, optimizes utilization, and improves maintenance scheduling.

- Increased Revenue and Customer Satisfaction: By improving inventory accuracy, accelerating processes, and enabling personalized services, RFID contributes to higher sales, better margins, and an enhanced customer experience.

- Streamlined Supply Chain Management: RFID provides end-to-end visibility and traceability across the entire supply chain, from raw materials to finished goods. This optimizes inbound/outbound flows, reduces loading/unloading times, and improves collaboration with supply chain partners.

- Enhanced Security and Loss Prevention: RFID tags can be embedded in products for instant authenticity identification and can trigger alarms if items are removed without authorization, providing robust anti-theft capabilities and protection against counterfeiting.

- Better Data Analytics and Insights: RFID generates vast amounts of real-time data that can be analyzed to identify patterns, trends, and actionable insights into operations, customer behavior, and supply chain performance, enabling continuous improvement.

- Improved Quality Control and Traceability: In manufacturing, RFID allows for monitoring components and assemblies at each production stage, identifying defects early, and ensuring complete product traceability for quality assurance and regulatory compliance.

Features & Benefits of RFID Solution

These are the key features and benefits of adopting an RFID Solutions

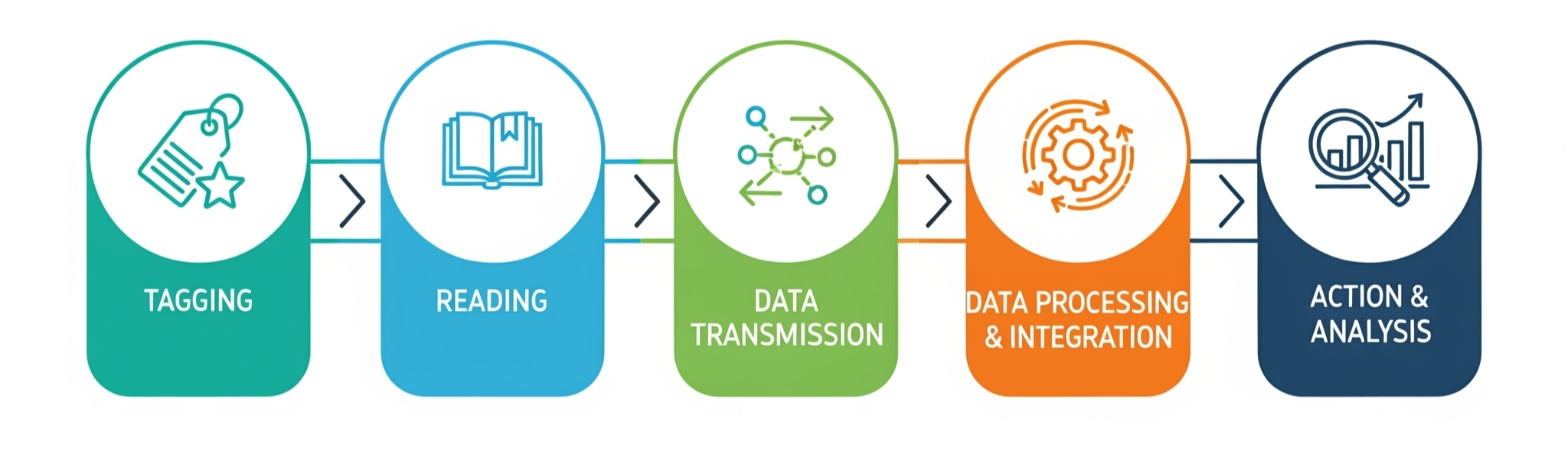

How does an RFID Solution works

- Tagging: Each item, asset, or product intended for tracking is affixed with an RFID tag. This tag consists of a microchip that stores a unique identifier and other relevant data, and an antenna to transmit and receive radio signals.

- Reading: RFID readers, strategically placed at key points (e.g., doorways, production lines, warehouse aisles), emit radio waves. When an RFID tag enters the reader’s range, it receives energy from these waves (for passive tags) or uses its own power source (for active tags) to activate and transmit its stored data back to the reader.

- Data Transmission: The RFID reader captures the data from the tags and converts it into a digital format. This data is then typically sent via network connections (wired or wireless) to a central middleware or software application, like a RFID Solution.

- Data Processing & Integration: Middleware acts as a bridge, filtering and aggregating the raw RFID data before sending it to the core business systems, such as an Enterprise Resource Planning (ERP) system or a Warehouse Management System (WMS). This ensures only relevant, clean data is passed on, preventing data overload.

- Action & Analysis: The integrated software then processes this real-time data. For example, it can automatically update inventory levels, track asset movements, trigger alerts for low stock, or provide detailed reports for analysis. This enables automated decision-making and provides valuable insights into operations.

Implementation of RFID Solution

Discovery & Assessment:

Define Objectives: Clearly identify the pain points the RFID solution aims to solve (e.g., improve inventory accuracy, enhance asset tracking, streamline supply chain).

Feasibility Study: Assess the existing infrastructure, operational workflows, and potential environmental interferences (e.g., metal, liquids) that might impact RFID performance.

System Audit: Evaluate current WMS and ERP capabilities to determine integration requirements.

Team Formation: Assemble a cross-functional project team including IT, operations, logistics, and management.

Solution Design & Planning:

Tag Selection: Choose the appropriate RFID tag types (passive, active, frequency, form factor) based on the items to be tracked and the environment.

Reader Placement Strategy: Determine optimal locations for RFID readers and antennas to ensure comprehensive coverage and accurate data capture.

Network Infrastructure: Plan for necessary network upgrades, including Power over Ethernet (PoE) and cabling, to support reader connectivity.

Software & Integration Architecture: Design the middleware and API solutions to ensure seamless data flow between RFID hardware and existing WMS/ERP systems.

Detailed Timeline & Budget: Develop a comprehensive project plan with milestones and allocate necessary resources.

Procurement & Installation:

Hardware Procurement: Purchase RFID tags, readers, antennas, printers/encoders, and any necessary accessories.

Infrastructure Deployment: Install network cabling, PoE infrastructure, and mount readers and antennas according to the design plan.

Tagging: Apply RFID tags to inventory items, assets, or products.

Software Configuration & Integration:

- Middleware Setup: Configure the RFID middleware to filter, process, and manage data from readers.

- WMS/ERP Integration: Develop and implement the necessary APIs or connectors to integrate the RFID data with existing business systems. This might involve custom development depending on system compatibility.

- Database Setup: Ensure the backend databases are configured to handle the volume of RFID data.

Testing & Optimization (Pilot Phase):

Controlled Deployment: Implement the RFID solution in a small, controlled environment (pilot program) to test functionality and identify issues.

Data Accuracy Testing: Verify the accuracy and reliability of RFID reads and data transmission.

Workflow Validation: Test how the RFID system impacts existing operational workflows and identify areas for optimization.

Troubleshooting: Address any technical glitches, read errors, or integration challenges.

User Feedback: Gather feedback from personnel using the system to refine configurations and processes.

Training & Rollout:

Employee Training: Train warehouse staff, IT teams, and other relevant personnel on how to use the new RFID system and its integrated processes effectively.

Phased Rollout: Gradually expand the RFID implementation across all relevant areas of the business based on the success of the pilot.

Ongoing Support: Establish clear channels for ongoing technical support and maintenance.

Monitoring & Continuous Improvement:

Performance Monitoring: Continuously monitor the system’s performance, read rates, and data accuracy.

Audits & Optimization: Conduct periodic audits and optimize reader placements, antenna tuning, and software configurations to maximize efficiency and capture rate.

Reporting & Analytics: Utilize RFID-generated data for continuous process improvement and strategic decision-making.

Use Cases of RFID Solutions

Retail

In retail, scanning and data capture systems are crucial for managing inventory and enhancing customer experience. Barcode scanning powers swift point-of-sale transactions, while RFID provides real-time stock levels, reducing shelf gaps. This technology optimizes the supply chain and gives retailers valuable insights into consumer behaviour for improved efficiency.

Healthcare

In hospitals, automated data capture is critical for patient safety and efficiency. Technologies like RFID wristbands ensure positive patient identification for procedures and medication, drastically reducing errors. Barcode scanning and digital tags also streamline the tracking of vital equipment and lab specimens, improving workflows and ensuring high-quality care.

Childcare

In childcare, modern identification systems enhance safety and communication. Secure check-in and check-out using biometrics or QR codes ensures only authorized guardians gain access. Digital tracking of attendance and daily activities provides parents with real-time updates, fostering a secure, efficient, and transparent environment for every child.

Manufacturing

In a factory, RFID tags can be attached to individual components or assemblies as they move through different production stages. Readers at each workstation automatically record the item’s status, enabling real-time visibility of the production line. This helps identify bottlenecks, ensures correct parts are used, optimizes production flow, and facilitates quality control by tracing defective parts back to their origin. For example, an automotive manufacturer can track engine blocks from casting to final assembly, ensuring each step is completed and logged accurately.

Supply Chain

RFID tags can provide a digital fingerprint for products, offering end-to-end traceability from the point of manufacture to the consumer. This is crucial for industries dealing with high-value goods, perishables, or products requiring strict regulatory compliance. Businesses can monitor product authenticity, track recalls, and prevent grey market diversion. For a pharmaceutical company, RFID ensures the integrity of the cold chain for temperature-sensitive drugs and verifies the authenticity of medicines, combating counterfeiting.

Education

In the education sector, AIDC technologies are crucial for modernizing campus operations. From RFID smart cards for library loans and secure building access, to barcodes for tracking IT assets and lab equipment, AIDC automates key processes. This streamlines administration, enhances security, and improves resource management across schools and universities.

Logistics

RFID can revolutionize warehouse operations. Instead of manually scanning each barcode, a handheld or fixed RFID reader can scan hundreds of tagged items on pallets or shelves simultaneously. This provides real-time, highly accurate inventory counts, automates goods receiving and dispatch, and enables quick location of specific items. This leads to reduced stockouts, optimized storage space, faster order fulfillment, and significant labor cost savings. A large distribution center for electronics, for instance, can drastically cut down inventory cycle count times from days to hours.

Construction & Industrial

On large construction sites or in industrial facilities, tools and equipment are often misplaced or lost, leading to significant delays and replacement costs. RFID tags on tools allow for quick and accurate check-in/check-out processes, real-time location tracking, and automated inventory of tool cribs. This improves accountability, reduces downtime, and optimizes tool utilization. A construction firm can quickly locate a specific power drill or heavy machinery on a sprawling job site.

Facility Management

In facility management, AIDC technologies are essential for optimizing building operations. By using RFID and barcodes for real-time asset tracking and QR codes on equipment for instant maintenance history access, managers streamline workflows. This enhances preventive maintenance, secures access control, and provides data-driven insights for more efficient and cost-effective management.

Frequently Asked Questions (FAQ) on RFID

What is RFID?

RFID stands for Radio-Frequency Identification. It’s an automatic identification technology that uses radio waves to wirelessly identify and track objects, animals, or people. An RFID system typically comprises RFID tags, an RFID reader, and an antenna, all connected to a host computer system.

How does RFID work at a fundamental level?

An RFID reader emits radio waves to activate and communicate with RFID tags. When a tag enters the reader’s radio frequency field, it transmits its unique data back to the reader. The reader then converts these radio waves into digital data, which is sent to a computer system for processing, analysis, and integration with existing business applications.

What are the key components of an RFID system?

The core components include:

- RFID Tag (Transponder): Consists of a microchip for data storage and an antenna for communication.

- RFID Reader (Interrogator): A device that transmits and receives radio signals to/from tags.

- Antenna: Facilitates the transmission and reception of radio waves between the reader and the tag.

- RFID Software/Middleware: Processes and manages the data collected from readers, integrating it with backend systems like ERP or WMS.

What are the different types of RFID tags and their primary uses?

RFID tags are primarily categorized by their power source:

- Passive RFID Tags: No internal power source; they draw power from the reader’s radio waves. They are inexpensive, small, and have a shorter read range (a few centimeters to ~15 meters). Ideal for inventory, asset tracking, and access control.

- Active RFID Tags: Have their own power source (battery). They offer a longer read range (up to 150 meters or more) and can transmit data continuously. Used for real-time locating systems (RTLS), vehicle tracking, and monitoring high-value assets.

- Semi-Passive (Battery-Assisted Passive – BAP) Tags: Have a battery to power the microchip but rely on the reader’s power for communication. They offer enhanced features like sensor integration and better read range than passive tags.

How does RFID compare to barcodes, and why might a business choose RFID?

RFID offers significant advantages over barcodes:

- Line of Sight: RFID does not require line of sight for reading, unlike barcodes.

- Multiple Reads: RFID can read multiple tags simultaneously (bulk reading), while barcodes are read one by one.

- Data Storage: RFID tags can store more data and can often be re-written, unlike static barcodes.

- Durability: RFID tags are often more durable and can withstand harsher environments.

- Automation: RFID enables greater automation of data capture, reducing manual errors and labor. Businesses choose RFID for greater automation, real-time visibility, improved accuracy, and applications where line-of-sight reading is impractical or inefficient.

What factors can affect RFID system performance, particularly around metal and liquids?

Metal and liquids can significantly interfere with RFID signals, especially for UHF (Ultra-High Frequency) tags. Metal can reflect signals, creating dead spots, while liquids can absorb them. Proper tag selection (e.g., on-metal tags), antenna placement, and system calibration are crucial to mitigate these issues and ensure reliable performance in challenging environments.

Is RFID technology secure, and what measures are in place to protect data?

Security is a valid concern. RFID systems can be secured through:

- Encryption: Encrypting data transmitted between tags and readers to prevent eavesdropping.

- Authentication: Implementing protocols to ensure only authorized readers can communicate with tags and vice versa.

- Password Protection: Protecting data on read/write tags with passwords.

- Kill Commands: For some tags, a “kill” command can permanently deactivate the tag to prevent further reading, especially for consumer goods post-purchase.

- Physical Security: Securing readers and infrastructure to prevent tampering.

What industries are currently leveraging RFID solutions effectively?

RFID is transforming operations across numerous sectors, including:

- Manufacturing: For WIP tracking, tool management, and quality control.

- Retail: For inventory accuracy, loss prevention, and omnichannel fulfillment.

- Logistics & Supply Chain: For real-time asset tracking, warehouse management, and end-to-end visibility.

- Healthcare: For tracking medical equipment, patient identification, and pharmaceutical management.

- Automotive: For component tracking, vehicle assembly, and parts management.

- Aerospace & Defense: For maintenance, repair, and overhaul (MRO) operations and asset management.

What is the typical cost of an RFID solution for a business, and what drives these costs?

The cost varies significantly based on scale, complexity, and components depending on operational needs. The whole solution would consist of Tags, Readers, Antennas, Printers/Encoders, Software & Integration, Installation & Services. Contact us for a consultation session to find out more

Can RFID solutions be integrated with existing Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS)?

Absolutely. Integration with ERP and WMS is a critical aspect of modern RFID deployments. Middleware solutions are often used to act as a bridge between the RFID hardware (readers, tags) and the existing software infrastructure. This allows real-time RFID data (e.g., inventory updates, asset locations) to flow seamlessly into the ERP/WMS, automating processes, enhancing data accuracy, and providing a comprehensive view of operations.

What is the return on investment (ROI) typically seen from implementing RFID?

The ROI for RFID solutions can be substantial and rapid, often achieved within 12-24 months. Businesses typically see returns through:

- Reduced Labor Costs: Automation of manual counting and tracking.

- Minimized Shrinkage/Losses: Improved accuracy and anti-theft capabilities.

- Optimized Inventory Levels: Reduced overstocking and fewer stockouts.

- Increased Productivity: Faster workflows and reduced downtime.

- Enhanced Customer Satisfaction: Better product availability and efficient service.

- Improved Compliance: Streamlined data for regulatory requirements.

How does Autopack ensure the quality and performance of its RFID solutions?

Autopack focuses on providing robust and reliable RFID solutions. While specific details would be provided during a consultation, general practices for quality assurance in RFID solutions include:

- High-Quality Hardware: Sourcing durable and high-performing RFID tags, readers, and antennas. Autopack is the platinum partner for Zebra, a leading brand in the AIDC.

- Optimized Software: Developing or integrating with best-in-class software solutions for data processing and management.

- Expert System Design: Employing experienced engineers to design optimal reader placement and system architecture.

- Rigorous Testing: Conducting comprehensive testing, including pilot programs, to ensure system accuracy and reliability in real-world conditions.

- Ongoing Support and Maintenance: Providing continuous technical support, preventive maintenance, and system optimization services to ensure long-term performance.

Ready to transform your business?

Contact us at sales@autopack1.com or call 6288 2112 to get started today.